Meer dan 10.000 industriële onderdelen en verbruiksartikelen verkocht

Sneller verkopen! Plaats artikelen sneller en wereldwijd!

2 jaar garantie op alle artikelen

Human-Machine Interface (HMI) and Open Interface Panels are critical components in modern industrial automation and control systems. Here’s an overview of both concepts: Human-Machine Interface (HMI) Definition: HMI refers to the user interface that connects operators to the machine or system they are controlling. It allows users to interact with the machinery, monitor processes, and input commands. Key Features: 1. Visualization: Displays real-time data, trends, and system status through graphical representations. 2. Control: Enables operators to control machinery and processes through touch screens, buttons, or other input methods. 3. Alerts and Notifications: Provides alarms and notifications for abnormal conditions or system failures. 4. Data Logging: Records operational data for analysis, troubleshooting, and compliance. 5. User Management: Supports multiple user roles with varying levels of access and control. Applications: - Manufacturing processes - Energy management systems - Transportation systems - Building automation ### Open Interface Panels Definition: Open Interface Panels are HMI systems designed with open standards and protocols, allowing for greater flexibility and interoperability with various devices and systems. Key Features: 1. Interoperability: Can communicate with different devices and systems from various manufacturers, facilitating integration. 2. Customization: Users can customize the interface and functionality to meet specific needs without being locked into a single vendor's ecosystem. 3. Scalability: Easily scalable to accommodate future expansions or changes in the system. 4. Standard Protocols: Often utilize standard communication protocols (like OPC, MQTT, RESTful APIs) to ensure compatibility. Applications: - Smart factories and Industry 4.0 implementations - IoT applications - Systems requiring integration of legacy equipment with modern technology Benefits of HMI and Open Interface Panels 1. Improved Efficiency: Streamlined operations and reduced downtime through better monitoring and control. 2. Enhanced User Experience: Intuitive interfaces improve operator training and reduce errors. 3. Flexibility and Adaptability: Open interfaces allow for easy upgrades and integration of new technologies. 4. Cost-Effectiveness: Reduces the need for proprietary systems, lowering overall costs.

HMI & Open Interface Panels Fabrikanten

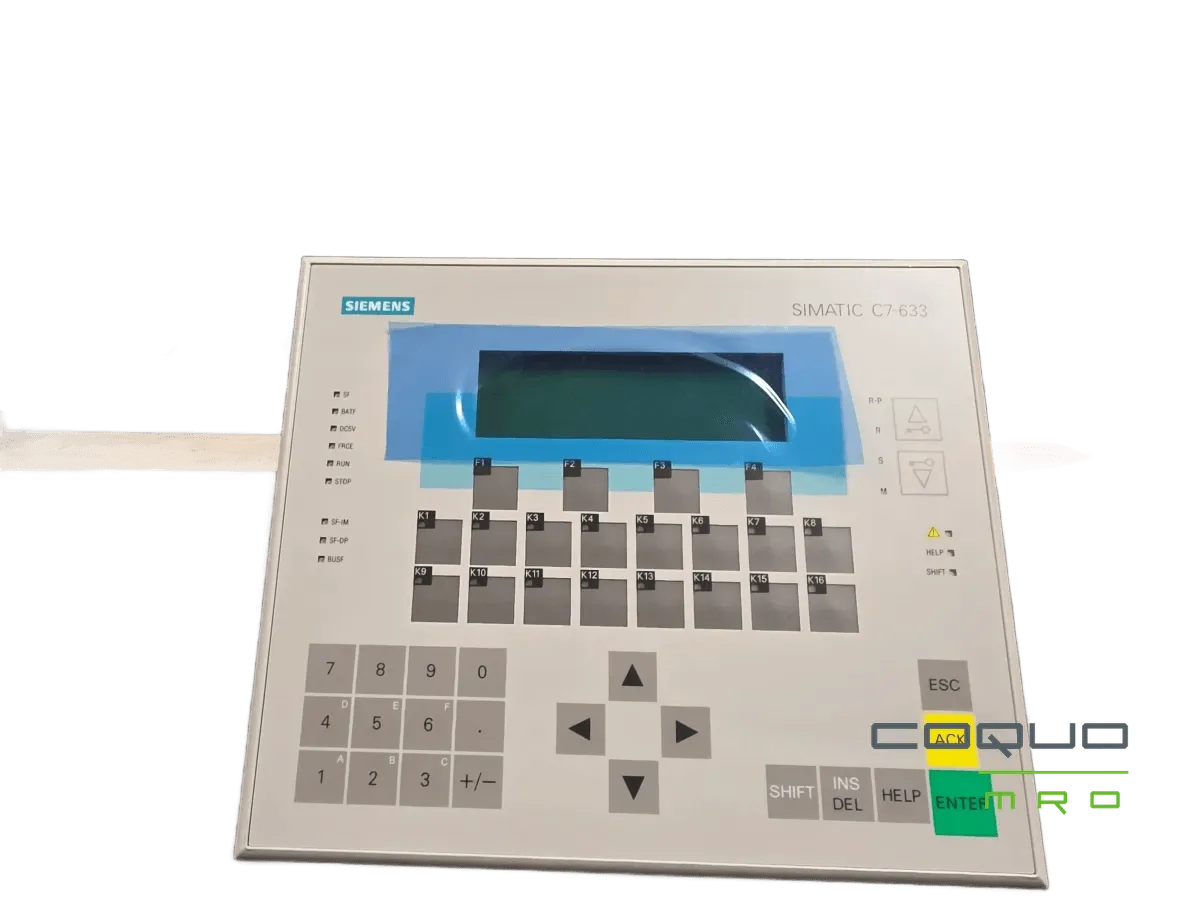

De SIMATIC® C7 besturingssystemen combineren een programmeerbare besturing en een bedieningspaneel in één unit. Hierdoor kunnen complete machinebesturingssystemen worden geïmplementeerd met minimale afmetingen, tegen een economische prijs. Aangezien de PLC's en OP's producten zijn uit het SIMATIC assortiment, zijn er ruime mogelijkheden om de C7 besturingssystemen uit te breiden en te integreren i...

Siemens - Simatic c7-433 P