Verkauft mehr als 10.000 Industrieteile und Verbrauchsmaterialien

Schneller verkaufen! Stellen Sie Artikel schneller und global ein!

2 Jahre Garantie auf alle Artikel

Level measurement refers to the process of determining the level of a substance, typically a liquid or solid, within a container, tank, or other storage facility. Accurate level measurement is crucial in various industries, including chemical processing, water treatment, food and beverage, oil and gas, and pharmaceuticals, among others. There are several methods and technologies used for level measurement, each with its own advantages and limitations. Here are some common methods: 1. Mechanical Methods - Float Switches: A float rises and falls with the liquid level, activating a switch at predetermined levels. - Bubblers: A tube is submerged in the liquid, and air is bubbled through it. The pressure of the air needed to maintain a constant flow correlates with the liquid level. 2. Capacitance Level Measurement - This method uses the change in capacitance caused by the presence of a dielectric material (the liquid) between two electrodes. It is suitable for both conductive and non-conductive liquids. 3. Ultrasonic Level Measurement - Ultrasonic sensors emit sound waves that reflect off the surface of the liquid. The time it takes for the sound waves to return is used to calculate the distance to the liquid surface, thus determining the level. 4. Radar Level Measurement - Similar to ultrasonic measurement, radar sensors use microwave signals to measure the distance to the liquid surface. They are effective in harsh conditions and can measure levels in a variety of materials. 5. Laser Level Measurement - Laser sensors emit a laser beam that reflects off the surface of the liquid. The time taken for the laser to return is used to calculate the distance to the surface. 6. Hydrostatic Pressure Measurement - This method measures the pressure exerted by the liquid column above a sensor. The pressure is directly proportional to the height of the liquid column, allowing for level calculation. 7. Magnetostrictive Level Measurement - This technology uses a magnetic float that moves along a guided rod. A magnetic field is generated, and the time it takes for a pulse to travel to the float and back is used to determine the level. 8. Optical Level Measurement - Optical sensors use light to detect the presence or absence of a liquid at a certain level. They are often used for point level detection. 9. Conductive Level Measurement - This method uses electrodes to detect the presence of conductive liquids. When the liquid makes contact with the electrodes, it completes a circuit, indicating the level. Considerations for Level Measurement - Type of Material: The choice of measurement method may depend on whether the material is a liquid or solid, as well as its properties (e.g., viscosity, density, conductivity). - Environmental Conditions: Factors such as temperature, pressure, and the presence of vapors or dust can affect measurement accuracy. - Accuracy and Range: Different methods offer varying levels of accuracy and measurement ranges, which should be matched to the application requirements. - Installation and Maintenance: Some methods may require more complex installation or maintenance than others.

Level Measurement Hersteller

M EHENDRESS+HAUSER LIQUIPHANT M IP66/1P67/NEMA 4X Bestellnummer: FTL51- BAE2BB4G5C 660 Schaltpunkt: 647 mm mm Ser.-Nr.: 7506D701027 10129881/000230 000 000 113G EExn C II T6 Il 3D T85°C AXA182F-B Made in Germany 79889 Maulburg CE Z-85.11-230 05.05 D01487-A

Endress+Hauser - LIQUIPHANT M

100 00 in Deutschland, D-79689 Maulburg Bestellnummer: FTL51-AAE2BB8G4C Nr. 8B03AB01027 Um 8,2VDC ±20% MUR IEC 60947-5-6 A/2.2...3,5mA Ta<=+70°C CTp<= +150°C CE (T&Ta +5 K Endress+Hauser E L = 250mm Schaltpunkt= 237mm (IP66/67/ NEVA MWP 275ps Dat: 1908

Endress+Hauser - FTL51-AAE2BB8G4C

100 00 in Deutschland, D-79689 Maulburg Bestellnummer: FTL51-AAE2BB8G4C Nr. 8B03AB01027 Um 8,2VDC ±20% MUR IEC 60947-5-6 A/2.2...3,5mA Ta<=+70°C CTp<= +150°C CE (T&Ta +5 K Endress+Hauser E L = 250mm Schaltpunkt= 237mm (SIL IP66/67/ NEVA MWP 275ps Dat: 1908

Endress+Hauser - FTL51-AAE2BB8G4C

Mettler-Toledo GmbH Geschäftsbereich Wägezellen CH-8606 Nänikon Made in Switzerland TBRICK 15-EX 4225213370 42101035 2004 Typ S/N ANR Baujahr Ex 20 EEx lb IIC T4 -10°C T +40°C 2D IP 66/67 T +55°C KEMA 03ATEX1130 X Siehe diese Kontrollzeichnungen 507244, 506382, 2-86-202-451-00 22006397, 22006477, 22006478 - Diese Wägezelle ist mandfaste unter einer oder mehreren der Spelente 5.205.369 5.3409159.20...

Mettler Toledo - TBRICK 15-EX

Behälter:D1102G Behälter: EH ENDRESS+HAUSER PROMASS I TMB W-System CE Bestellnummer: 631T16-FPHO0A25B1A 71 854629 Ser.Nr.: TAG-Nr.: K-Faktor: 3.5508 / 341 NEMA4X 3/4" Triclamp Größe: 1/2" FB TMmax: 300°F Materialien: TITAN Dichtekalibrierung: +/-0.020g/cc Surf 240grit 360psi Behälter A-C PatUS 4,768,384 4,801,897. Weitere Patente angemeldet UOM: EA SB96387 321263-0000

Endress+Hauser - PROMASS 63IT16-FPH00A25B1A

Typ Type KROHNE Duisburg Germany BM 70A Level-Radar |CE Vers. 3.05 Vk-Auftrag Sales Order: 710161/010 Serien-Nr. Serial-Nr. 2/326294.001 Baujahr Meẞstellen-Nr. Manufact 2002 Tag-No. Hilfsenergie Power Supply: Ausgangssignale: Outputsignals G490 XZ 353X Ꮓ 230 V AC +10%/-25% 4 ... 20 mA HART Datenschild am Flansch beachten Notice Data Label on Flange Pmax 20W/40VA

Krohne - BM 70A Level-Radar

FEL54 U: 19...253VAC, 50/60Hz oder 19...55VDC Kontaktbelastbarkeit: 30VDC, 6A; 125VDC, 0.2A 253VAC, 6A; 1500VA (cos=1) 750VA (cos -0,7) T Prozess max: 150°C PN max: 275psl D01388-E

Endress+Hauser - FEL54

6/33 327.002 SO: 808464/050 KO: 15560547 71285 V51001A0131110010 AC: P05010816924 KROHNE Duisburg Germany Level-Radar CE 0682 Typ : Type: BM 70A Vers. 3.07 Vk-Auftrag: Sales Order: 808464/050 Serien-Nr.: Serial-Nr.: 5/339327.002 Baujahr: Manufact.: 2005 Meßstellen-Nr.: Tag-No. 682374/20 : 260920050700 Order#: Hilfsenergie: Power Supply: Ausgangssignale: Outputsignals 24 V DC/AC 4 ... 20 mA HART Da...

Krohne - BM 70AI/E-E EEX

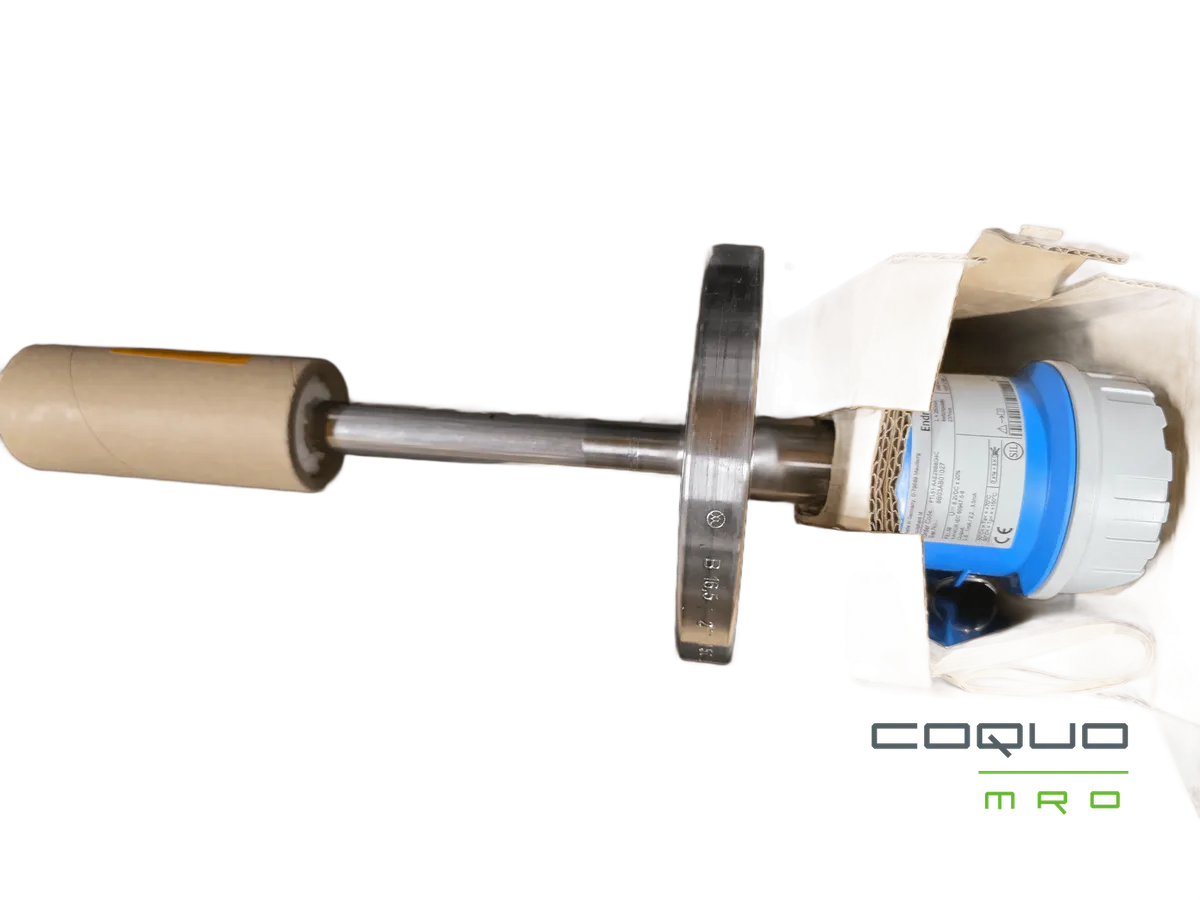

Vollständig isolierte Stabelektrode zur Füllstandsmessung oder Füllstandsmeldung insbesondere in leitfähigen Flüssigkeiten.

Endress+Hauser - Multicap T A11AY1BKY1-550mm