Prodáno více než 10 000 průmyslových dílů a spotřebního materiálu

Prodávejte rychleji! Vypisujte položky rychleji a globálně!

2letá záruka na všechny položky

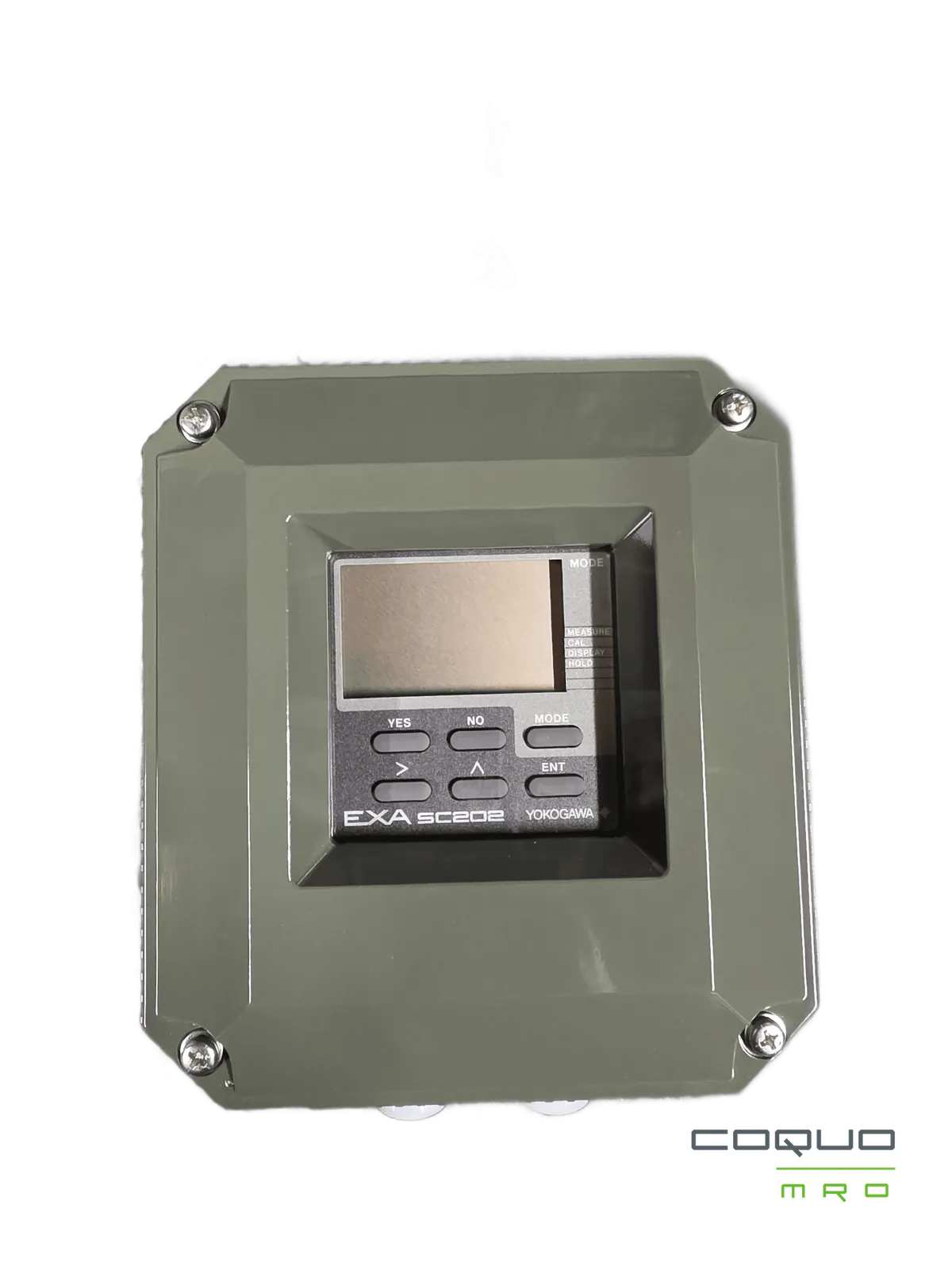

A conductivity transmitter is an instrument used to measure the electrical conductivity of a solution, which is an important parameter in various industrial and laboratory applications. Conductivity is a measure of a solution's ability to conduct electric current, which is influenced by the concentration of ions in the solution. Here’s an overview of the key aspects of conductivity transmitters: Key Components 1. Conductivity Sensor/Probe: This is the part of the system that comes into direct contact with the solution. It typically consists of two electrodes that measure the conductivity of the liquid. The design can vary, including two-electrode, four-electrode, or inductive sensors. 2. Transmitter Unit: This unit processes the signals from the sensor. It converts the raw data from the sensor into a readable output, which can be displayed locally or transmitted to a control system. 3. Display/Output Interface: Many conductivity transmitters come with a digital display that shows real-time conductivity readings. They may also have output options such as analog signals (4-20 mA), digital communication (Modbus, Profibus), or alarms for specific conductivity levels. Working Principle The conductivity of a solution is determined by measuring the current that flows between the electrodes when a voltage is applied. The relationship between the current and the applied voltage, along with the geometry of the electrodes, allows for the calculation of conductivity. Applications - Water Treatment: Monitoring the conductivity of water to ensure it meets quality standards. - Chemical Processing: Controlling the concentration of chemicals in solutions. - Food and Beverage Industry: Ensuring product quality and consistency. - Pharmaceuticals: Monitoring the purity of water used in drug manufacturing. - Environmental Monitoring: Assessing the quality of natural water bodies. Calibration and Maintenance Regular calibration is essential for accurate measurements. Calibration typically involves using standard solutions with known conductivity values. Maintenance may include cleaning the sensor to prevent fouling and ensuring that the electronics are functioning correctly. Considerations - Temperature Compensation: Conductivity can vary with temperature, so many transmitters include temperature compensation to provide accurate readings. - Range and Accuracy: Different applications may require different ranges and levels of accuracy, so selecting the right transmitter for the specific application is crucial. - Material Compatibility: The materials used in the sensor and transmitter should be compatible with the solution being measured to prevent corrosion or contamination.

Conductivity Transmitter Výrobci

PŘEVODNÍK KONDUKČNOSTI MODEL SC2029 SUFFIX A-E NAPÁJENÍ 24V DC VÝSTUP 4-20mA DC AMB. TEMP. -10 -55 °C STYL 63 č. 32K802294 2010.07 YOKOGAWA Made in Japan Tokyo 180-8750 JAPAN CE N200

Yokogawa - SC2029

PŘEVODNÍK KONDUKČNOSTI MODEL SUFFIX SC202 # NAPÁJENÍ 24V DC VÝSTUP 4-20mA DC AMB. TEMP. -10~55 °C STYL $3 No. 92XC01516 2010.10 YOKOGAWA Made in Japan Tokyo 180-8750 JAPAN CE ✔ N200

Yokogawa - SC202